Product Category

Contact Us

- +86-18721892398

- +86-18721892398

- [email protected]

- [email protected]

- J level 1,No 185 Moyu road,Anting,Jiading,Shanghai

- Home

- Products

- Sheet&Film Extrusion line

- PVC/WPC Foam Board Extrusion Line

PVC/WPC Foam Board Extrusion Line

Product Description

Production process:

Twin screw extruder —T Die—Cooling calibrator—-Cooling bracket—-Haul-off—-cutter—–Stacker

Application and features:

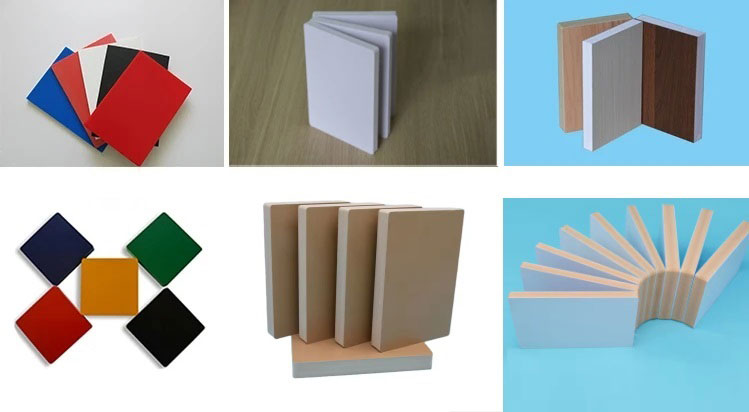

PVC/WPC foam board have properties of light weight and even foam, the best substitute for wood, aluminum and composite sheet; Good at function of moth proof, waterproof, moisture resistant; Fire retardant, prevent the spread of fire and self-extinguish, is a safe material for building decoration; High hardness, not easy to crack, strong load bearing capacity, is the ideal material for building decoration; Easy to process: Drilling, Nailing, Cutting, Sawing, Sticking. Which is widely used in below fields:

- Building outdoor wall board, indoor decoration board, partition board in office and house;

- Screen printing, flat solvent printing, engraving, billboard and exhibition display;

- Chemical anti corrosion project, special cold project, environmental protection;

- Sanitary ware, kitchen cabinets, washroom cabinets.

Main Technical Specification

| Power supply: | 380V /3 phase/ 50 Hz |

| Raw Material: | PVC/WPC Compounding |

| Extruder | CTE80-156/CTE80-173/CTE92-188 |

| Main motor power | 75kw/90kw/110kw |

| Sheet thickness: | 2-40mm |

| Net width of sheet: | 915~2050mm |

| Layer structure of sheet: | 1-layer/2-layer/3-layer |

| Extruding capacity: | 300-650kg/h |

Note: Information listed above are for reference only, the production line can be designed by customer’s requirements.