Product Category

Contact Us

- +86-18721892398

- +86-18721892398

- [email protected]

- [email protected]

- J level 1,No 185 Moyu road,Anting,Jiading,Shanghai

- Home

- Products

- Sheet&Film Extrusion line

- SPC Flooring Extrusion Line

SPC Flooring Extrusion Line

Product Description

Production process:

Extrusion Line: Twin screw extruder —T Die—Four/Five roller calender—-Cooling bracket—-Haul-off—-Guillotine—–Auto stacker

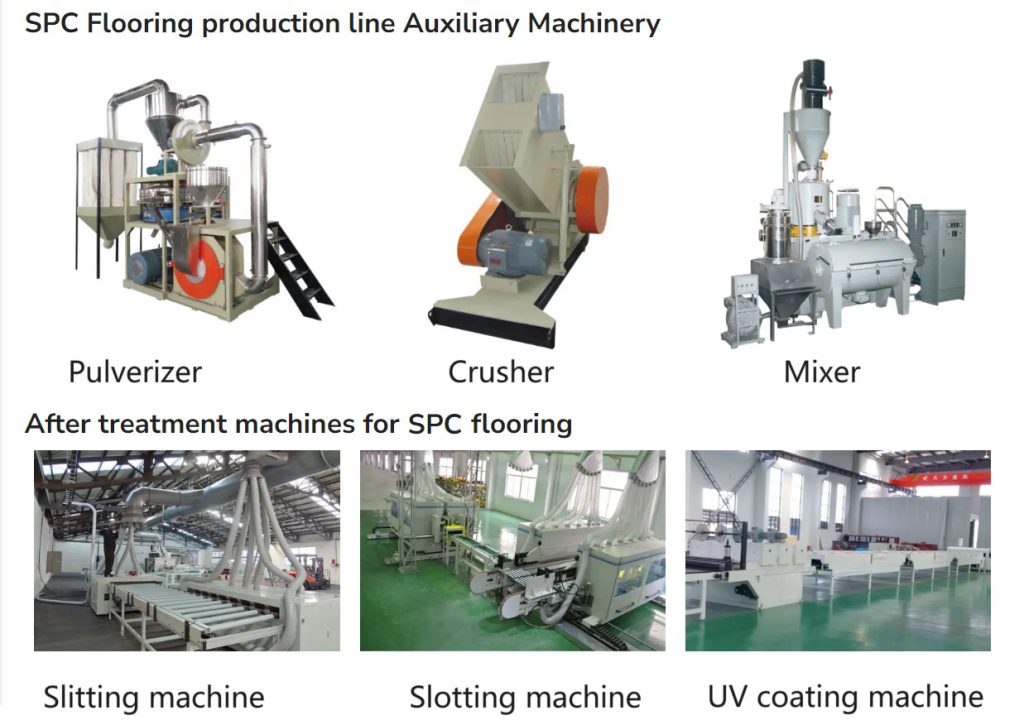

After Treatment machinery :UV coating—Sitting&Slotting—IXPE lamination

Performance and advantages:

- SPC Flooring production line will be energy saving, high efficient and stable.

- The embossing roller replacement be easier.

- Easy operation and maintenance and QC checking, and working with high safety

- Lamination system make the wearing layer have better plasticization and more peel strength on product surface.

- Pattern film and wearing film can connect, which make no waste during change winders.

- Suitable for special SPC flooring formulation, with good performance on shrinkage and bending.

- Equipped with embossing tracking system to make sure depth of embossing be even all the time.

- Make special design for SPC flooring production and offer turnkey project.

Application:

SPC flooring have feature on zero formaldehyde, mildew proof, moisture proof, fire resistance, mothproof and easy installation and so on. With excellent stability and durability, SPC flooring have solved the problem of nature wood flooring deformation problems, but also solve the formaldehyde problem of other decorative materials, it has many colors and patterns to choose, which suitable for indoor flooring decoration in hotel and hospital shopping malls and other public places. And compared with WPC flooring, SPC flooring’ production process is simple and low cost.

Main Technical Specification

| Power supply: | 380V /3 phase/ 50 Hz |

| Raw Material: | PVC Compounding |

| Sheet thickness: | 2-8mm |

| Net width of sheet: | 980/1250mm |

| Layer structure of sheet: | 1-layer/2-layer/3-layer |

| Extruding capacity: | 700-1500kg/h |

Note: Information listed above are for reference only, the production line can be designed by customer’s requirements.